Most modern electronic devices are now made with Surface Mount Technology (SMT). Sometimes you see the abbreviation SMD for Surface Mount Devices. They are cheaper to mass produce, but need some manufacturing setup which is often too expensive to do for prototypes or small quantities of boards.

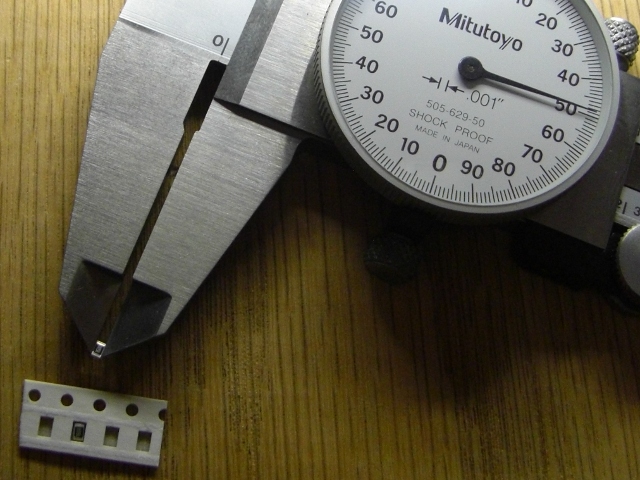

I’ve been working on a new SMT design and have been hand soldering the prototypes. These parts are really small.

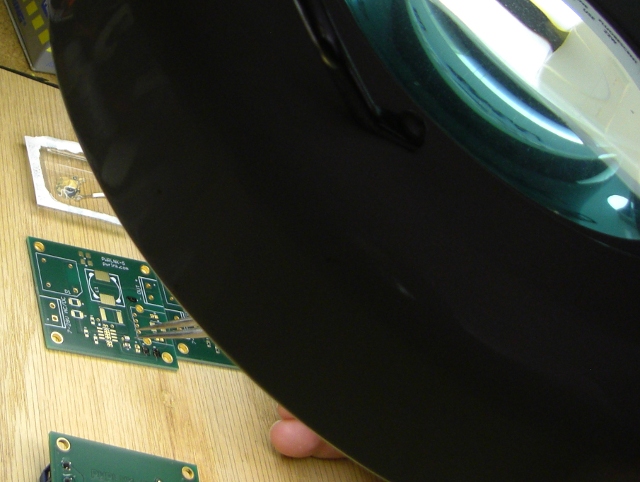

I need a magnifying worklight to see the details.

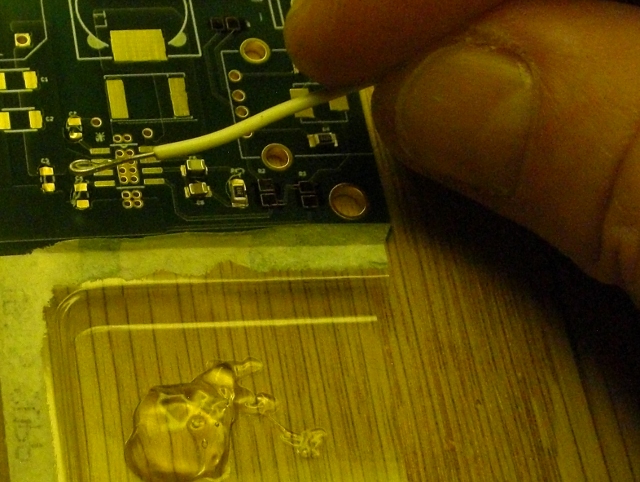

Tack flux is used to hold the parts to the board and to help the soldering by whetting or wicking. It isn’t an adhesive, just highly viscous, so it holds parts in place through a fair amount of vibration or bumping the board.

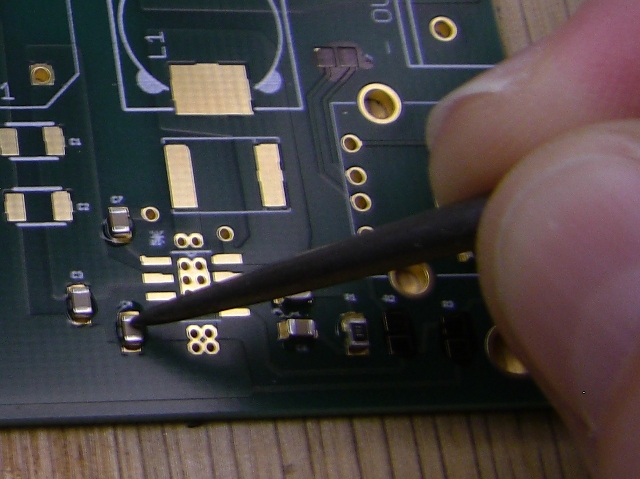

Pick up devices with tweezers and drop them onto the flux.

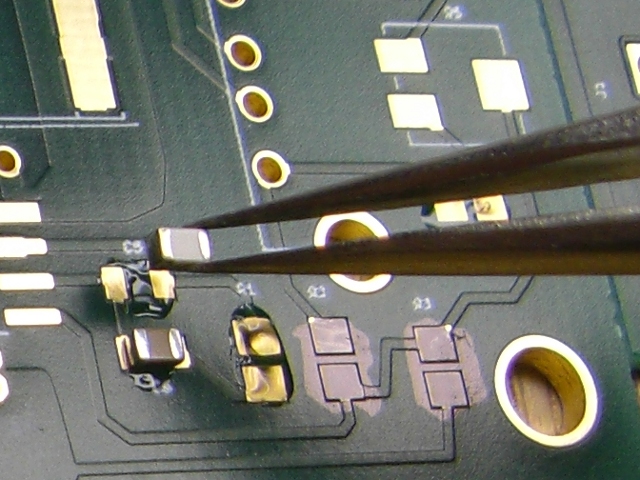

Use a probe to maneuver the part onto the pads.

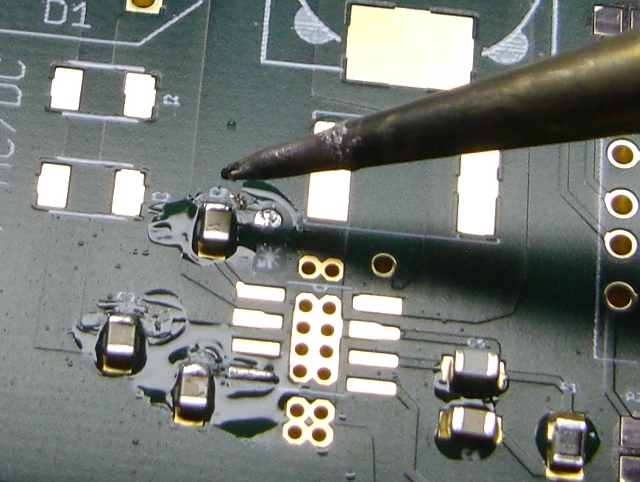

This part needs a bit of practice, so try it on larger parts first, then work your way to smaller ones. I can do 0805 which is 0.080 by 0.050 inches, but I avoid using 0403. I use a probe to position the part, then hold it down, get a tiny blob of solder on the iron tip. Then just wipe the tip of the soldering iron against the junction point, touching both parts of the connection, the part and the board. The flux makes a huge difference here, quickly wicking the solder into the gap between the part and the board.

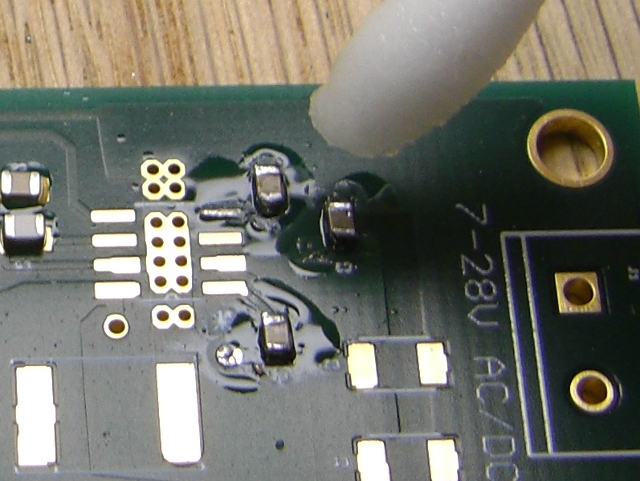

Clean up all the excess goo with a swab and alcohol. The tack flux is much easier to clean than the harder sticker flux they use in the core of the solder.

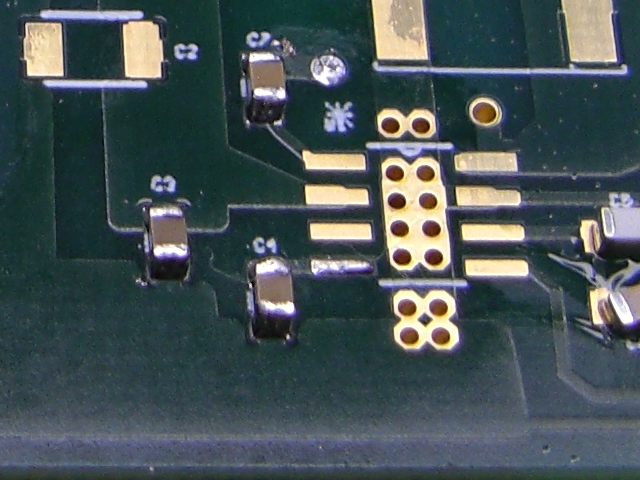

After the alcohol dries, the junctions are nice and shiny.

These boards have about two dozen parts each, so my technique has been improving through lots of practice.