Mead is the oldest of fermented alcoholic beverages, a wine made from honey. There are cave drawings of honey gathering from bees hives going back almost 10,000 years. If left to sit for a while, honey with a bit of wild yeast and water in a closed container pretty much make mead by themselves. Meads were enjoyed by the Vikings and very popular in England until the French invasion, when they were displaced by plentiful good quality grape wines.

I’ve looked at books that show how to make beer. So many steps! Boil this, mash that, put something in at just the right temperature, leave it in for the right amount of time, strain, re-boil, wash, etc, etc. And at the end, so many little bottles to wash and fill.

The hardest part of making mead is rehydrating the yeast and creating a good starter. Of course all brewing including beer and mead require clean equipment, and that can mean a certain amount of scrubbing. Clean first, then sanitize. I use StarSan acid sanitizer as the last step. It is very dangerous when undiluted, so take care. I mix it according to the directions (1 oz per 5 gallons of water) and then it seems quite safe. I do not wear gloves and haven’t had any irratation from it. Chlorine bleach works as a sanitizer too, but I found that needed too much rinsing. The StarSan doesn’t need to be rinsed, since the yeast can use the tiny bit of acid.

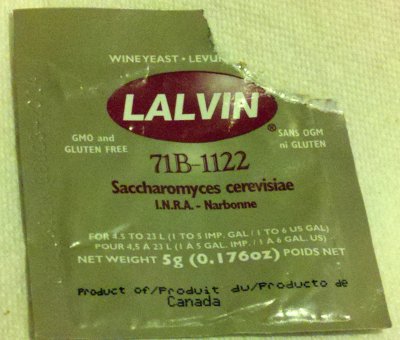

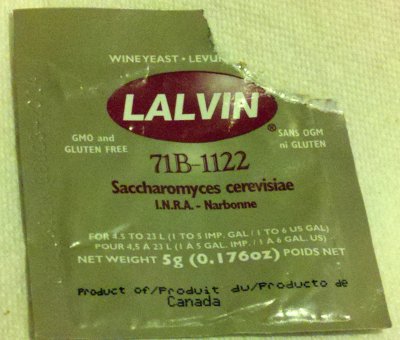

I use this Lalemand 71B-1122 for almost all of my meads, many of which are fruit varieties, called melomels. Most of the time, I make a 5 gallon bucket of ‘show mead’ like this one without extra flavors, just the honey itself. When that is finished fermenting, I siphon the mead into 1 gallon jugs with a pound of fruit or some spices, and let the mead age for a few months while it absorbs the flavors of the whole friut, skins and all (but not the pits).

Just get 30ml of distilled water to 105F (45C), stir in 5g of yeast nutrient, then stir in the yeast and let it sit for 15 minutes.

Yeasts are specific species of fungi that live in wet environments without oxygen. They need oxygen to muliply, but later I’ll seal the vessel, with a bubble trap to let out the pressure build up, so they can start converting sugars to alcohol and carbon dioxide. If all is well it will start to foam. Carl Sagan would be proud – eventually there will be billions and billions – a billion yeast cells per cubic centimeter.

Then make up a quart (liter) jar about 1/2 full of 90F water with a teaspoon of sugar. The yeast mixture will have cooled to a similar temperature and it is important not to shock the yeast by cooling it too fast. Pour the foamy yeast mixture into the jar and give it a quick stir. This is the starter. Left on its own for a while, it will continue to foam.

Now for the ‘must’, the mixture of ingredients that becomes the mead, what beer makers call the ‘wort’. This is essentially a big food grade plastic bucket with 8 to 20 pounds of honey with water, and the starter, stirred very well. Look in books or online for mead recipes, the amount of honey to use depends on whether you desire a dry or sweet mead, or something in between.

I recommend “The Compleat Meadmaker” by Ken Schramm, spelled the old English way.

This batch is to be a sweet mead based on honey from a local apiary in the Santa Cruz Mountains. Here I am using 9 lbs of dark, 8 lbs of light, and 5 lbs of clover with spring water to make 5.5 gallons. The honey was crystalized, so I diluted it with warm water the day before and poured back into the orginal jars. It all gets diluted when making mead anyway so there is no harm in doing it this way, and it took a few hours just to get everything liquid again, so doing that the day before was a good way to break up the work. The crystals can be seen on at the bottom of some jars.

The stirring oxygenates the must, giving the yeast a chance to get good start. I use a hand mixer plunging in and out of the liquid to create a good froth. The temperature of the must should be about 80F when you dump in the starter, so heat some of the water. This is essentially a no heat process, unlike beer making with its endless boiling. Of course beer makers need to get the sugars out of grain. The yeast need no help to get the sugars from honey and boiling the mixture would expell many of the aromatics, so I avoid heat as much as possible.

The standard way to get a particular alcohol result is to watch as the specific gravity changes and use Camden tablets (sulfites) to kill the yeast when you have the right numbers. But some people have bad reactions to sulfites.

The more natural way is to plan ahead knowing the alcohol tolerance of your yeast and put in enough sugars that there will be residuals when the yeast reaches its tolerance point.

I haven’t derived this myself, but the rule of thumb is ABV = 133 * ( FG – OG ). Alcohol By Volume is 133 times the difference between the Final specific Gravity and the Original specific Gravity.

After 24 hours, I filled the hydrometer sample tube. The must was bubbling like crazy and it took a few minutes to settle down enough to get a reading. In the first few days the specific gravity can drop by as much as 10 points a day, though it’s a waste of 4 precious ounces for each measurement, so after the first couple of days, I make my self wait for a week between checks.

When the yeast has done its job it will die off and settle to the bottom, and the mead will become clear. Then I drain from the bucket and put the mead into glass bottles of various sizes to age. Some by itself, some with fruit. Then it’s best to forget about them for a few months. This is a slow hobby, and good things come to those who wait.